This international retailer was struggling with high levels of inventory in stores and central depots, but in the wrong mix for the rate of sales. Its inability to coordinate the flow of goods from long lead time suppliers to stores was causing repeated air-frighting to cover shortages. Yet working capital was above target.

Eliminating unnecessary air-freight for an international retailer

Challenge

Approach

The SupplyVue analytics tool was used to capture transactional demand and inventory data. SupplyVue was able to analyse the demand profiles of the product portfolio, identifying base demand and promotional demand separately. Additionally SupplyVue analysed the supply chain performance, processes and parameters settings by segment to investigate the root cause of the air-freight requirement.

Assessment

Description

Demand was not segmented despite obvious differences between Fashion and Steady items

No differentiated replenishment policy based on segment

Reliance on freight to alleviate stock issues

No forecasting despite forecastable demand at regional level for “Steady items”

Future State

Using SupplyVue the team segmented the demand between basic and promotional products. Using a modelled forecast accuracy generated by the statistical algorithm from basic items, SupplyVue calculated the required inventory policies at the central warehouse and recalculated the corresponding inventory levels at store (based on a Kanban pull mechanism from the central inventory).

For these items the demand profile is stable and predictable enough so that even with an overall reduction in the total inventory in the network there is enough cover at the central warehouse to eliminate air freight caused by inventory shortages. Promotional items should continue to be managed separately as at present.

Even though the safety cover at the central warehouse was set at a high level (99%) cover there is still the chance of stock-outs. So these situations need to be predicted and managed.

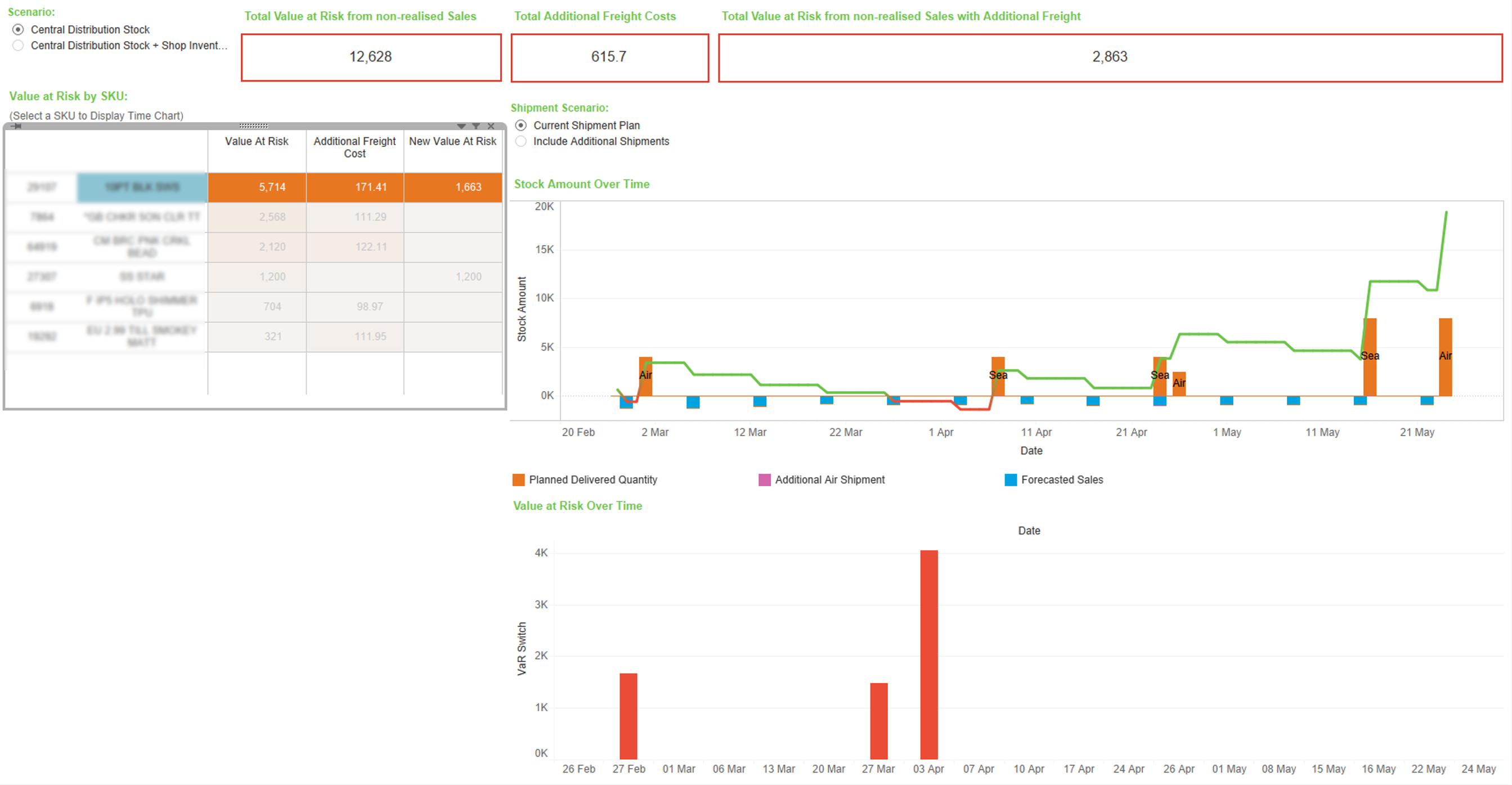

SupplyVue’s planning and analysis capability should be used to predict the products with the high chances of shortage based on latest forecast and provide an evaluation of the likely margin lost before the next planned replenishment and compare this to the cost of air-freight. This allows managers to take an informed decision on whether to air-freight or not.